Your personal Tumblr journey starts here

Technology - Blog Posts

Setting the Standards for Unmanned Aircraft

From advanced wing designs, through the hypersonic frontier, and onward into the era of composite structures, electronic flight controls, and energy efficient flight, our engineers and researchers have led the way in virtually every aeronautic development. And since 2011, aeronautical innovators from around the country have been working on our Unmanned Aircraft Systems integration in the National Airspace System, or UAS in the NAS, project.

This project was a new type of undertaking that worked to identify, develop, and test the technologies and procedures that will make it possible for unmanned aircraft systems to have routine access to airspace occupied by human piloted aircraft. Since the start, the goal of this unified team was to provide vital research findings through simulations and flight tests to support the development and validation of detect and avoid and command and control technologies necessary for integrating UAS into the NAS.

That interest moved into full-scale testing and evaluation to determine how to best integrate unmanned vehicles into the national airspace and how to come up with standards moving forward. Normally, 44,000 flights safely take off and land here in the U.S., totaling more than 16 million flights per year. With the inclusion of millions of new types of unmanned aircraft, this integration needs to be seamless in order to keep the flying public safe.

Working hand-in-hand, teams collaborated to better understand how these UAS's would travel in the national airspace by using NASA-developed software in combination with flight tests. Much of this work is centered squarely on technology called detect and avoid. One of the primary safety concerns with these new systems is the inability of remote operators to see and avoid other aircraft. Because unmanned aircraft literally do not have a pilot on board, we have developed concepts allowing safe operation within the national airspace.

In order to better understand how all the systems work together, our team flew a series of tests to gather data to inform the development of minimum operational performance standards for detect and avoid alerting guidance. Over the course of this testing, we gathered an enormous amount of data allowing safe integration for unmanned aircraft into the national airspace. As unmanned aircraft are becoming more ubiquitous in our world - safety, reliability, and proven research must coexist.

Every day new use case scenarios and research opportunities arise based around the hard work accomplished by this incredible workforce. Only time will tell how these new technologies and innovations will shape our world.

Want to learn the many ways that NASA is with you when you fly? Visit nasa.gov/aeronautics.

Make sure to follow us on Tumblr for your regular dose of space: http://nasa.tumblr.com.

5 Out of this World Experiments Awaiting Crew-1 Space Scientists

NASA astronauts Shannon Walker, Victor Glover, and Mike Hopkins, and JAXA (Japan Aerospace Exploration Agency) astronaut Soichi Noguchi embark on a historic mission on November 14, 2020 aboard the Crew Dragon. NASA’s Crew-1 mission marks the first certified crew rotation flight to the International Space Station. During their 6-month stay on orbit, these crew members will don their science caps and complete experiments in microgravity. Check out five out of this world experiments you can expect to see these space scientists working on during Expedition 64.

1. Space Gardening

The Crew-1 astronauts will become space farmers with the responsibility of tending to the rad(ish) garden located in a facility known as the Advanced Plant Habitat (APH). Researchers are investigating radishes in the Plant Habitat-02 experiment as a candidate crop for spaceflight applications to supplement food sources for astronauts. Radishes have the benefits of high nutritional content and quick growth rates, making these veggies an intriguing option for future space farmers on longer missions to the Moon or Mars.

2. Micro Miners

Microbes can seemingly do it all, including digging up the dirt (so to speak). The BioAsteroid investigation looks at the ability of bacteria to break down rock. Future space explorers could use this process for extracting elements from planetary surfaces and refining regolith, the type of soil found on the moon, into usable compounds. To sum it up, these microbial miners rock.

3. Cooler Exploration Spacesuits

The iconic spacesuits used to walk on the moon and perform spacewalks on orbit are getting an upgrade. The next generation spacesuit, the Exploration Extravehicular Mobility Unit (xEMU), will be even cooler than before, both in looks and in terms of ability to regulate astronaut body temperature. The Spacesuit Evaporation Rejection Flight Experiment (SERFE) experiment is a technology demonstration being performed on station to look at the efficiency of multiple components in the xEMU responsible for thermal regulation, evaporation processes, and preventing corrosion of the spacesuits.

4. Chips in Space

Crew-1 can expect to get a delivery of many types of chips during their mission. We aren’t referring to the chips you would find in your pantry. Rather, Tissue Chips in Space is an initiative sponsored by the National Institutes of Health to study 3D organ-like constructs on a small, compact devices in microgravity. Organ on a chip technology allows for the study of disease processes and potential therapeutics in a rapid manner. During Expedition 64, investigations utilizing organ on a chip technology will include studies on muscle loss, lung function, and the blood brain barrier – all on devices the size of a USB flashdrive.

5. The Rhythm of Life

Circadian rhythm, otherwise known as our "internal clock," dictates our sleep-wake cycles and influences cognition. Fruit flies are hitching a ride to the space station as the subjects of the Genes in Space-7 experiment, created by a team of high school students. These flies, more formally known as the Drosophila melanogaster, are a model organism, meaning that they are common subjects of scientific study. Understanding changes in the genetic material that influences circadian rhythm in microgravity can shed light on processes relevant to an astronaut’s brain function.

Make sure to follow us on Tumblr for your regular dose of space: http://nasa.tumblr.com

For updates on other platforms, follow @ISS_Research, Space Station Research and Technology News, or our Facebook to keep up with the science happening aboard your orbiting laboratory, and step outside to see the space station passing over your town using Spot the Station.

Tomorrow’s Technology on the Space Station Today

Tablets, smart appliances, and other technologies that are an indispensable part of daily life are no longer state-of-the-art compared to the research and technology development going on over our heads. As we celebrate 20 years of humans continuously living and working in space aboard the International Space Station, we’re recapping some of the out-of-this-world tech development and research being done on the orbiting lab too.

Our Space Technology Mission Directorate (STMD) helps redefine state-of-the-art tech for living and working in space. Here are 10 technologies tried and tested on the space station with helping hands from its astronaut occupants over the years.

1. Astronaut Wanna-Bees

Astronauts on the space station are responsible for everything from conducting science experiments and deploying satellites to tracking inventory and cleaning. While all are necessary, the crew can delegate some jobs to the newest robotic inhabitants – Astrobees.

These cube-shaped robots can work independently or in tandem, carrying out research activities. Once they prove themselves, the bots will take on some of the more time-consuming tasks, such as monitoring the status of dozens of experiments. The three robots – named Bumble, Honey, and Queen – can operate autonomously following a programmed set of instructions or controlled remotely. Each uses cameras for navigation, fans for propulsion, and a rechargeable battery for power. The robots also have a perching arm that lets them grip handrails or hold items. These free-flying helpers take advantage of another STMD technology called Gecko Grippers that “stick” to any surface.

2. Getting a Grip in Microgravity

We wanted to develop tools for grabbing space junk, and something strong and super-sticky is necessary to collect the diverse material orbiting Earth. So, engineers studied the gecko lizard, perhaps the most efficient “grabber” on this planet. Millions of extremely fine hairs on the bottom of their feet make an incredible amount of contact with surfaces so the gecko can hold onto anything. That inspired our engineers to create a similar material.

Now the Gecko Gripper made by OnRobot is sold on the commercial market, supporting industrial activities such as materials handling and assembly. The NASA gecko adhesive gripper that’s being tested in microgravity on the Astrobee robots was fabricated on Earth. But other small plastic parts can now be manufactured in space.

3. Make It, or Don’t Take It

Frequent resupply trips from Earth to the Moon, Mars, and other solar system bodies are simply not realistic. In order to become truly Earth-independent and increase sustainability, we had to come up with ways to manufacture supplies on demand.

A demonstration of the first 3D printer in space was tested on the space station in 2014, proving it worked in microgravity. This paved the way for the first commercial 3D printer in space, which is operated by Made In Space. It has successfully produced more than 150 parts since its activation in 2016. Designs for tools, parts, and many other objects are transmitted to the station by the company, which also oversees the print jobs. Different kinds of plastic filaments use heat and pressure in a process that’s similar to the way a hot glue gun works. The molten material is precisely deposited using a back-and-forth motion until the part forms. The next logical step for efficient 3D printing was using recycled plastics to create needed objects.

4. The Nine Lives of Plastic

To help fragile technology survive launch and keep food safe for consumption, NASA employs a lot of single-use plastics. That material is a valuable resource, so we are developing a number of ways to repurpose it. The Refabricator, delivered to the station in 2018, is designed to reuse everything from plastic bags to packing foam. The waste plastic is super-heated and transformed into the feedstock for its built-in 3D printer. The filament can be used repeatedly: a 3D-printed wrench that’s no longer needed can be dropped into the machine and used to make any one of the pre-programmed objects, such as a spoon. The dorm-fridge-sized machine created by Tethers Unlimited Inc. successfully manufactured its first object, but the technology experienced some issues in the bonding process likely due to microgravity’s effect on the materials. Thus, the Refabricator continues to undergo additional testing to perfect its performance.

5. Speed Metal

An upcoming hardware test on the station will try out a new kind of 3D printer. The on-demand digital manufacturing technology is capable of using different kinds of materials, including plastic and metals, to create new parts. We commissioned TechShot Inc. to build the hardware to fabricate objects made from aerospace-grade metals and electronics. On Earth, FabLab has already demonstrated its ability to manufacture strong, complex metal tools and other items. The unit includes a metal additive manufacturing process, furnace, and endmill for post-processing. It also has built-in monitoring for in-process inspection. When the FabLab is installed on the space station, it will be remotely operated by controllers on Earth. Right now, another printer created by the same company is doing a different kind of 3D printing on station.

6. A Doctor’s BFF

Today scientists are also learning to 3D print living tissues. However, the force of gravity on this planet makes it hard to print cells that maintain their shape. So on Earth, scientists use scaffolding to help keep the printed structures from collapsing.

The 3D BioFabrication Facility (BFF) created by TechShot Inc. could provide researchers a gamechanger that sidesteps the need to use scaffolds by bioprinting in microgravity. This first American bioprinter in space uses bio-inks that contain adult human cells along with a cell-culturing system to strengthen the tissue over time. Eventually, that means that these manufactured tissues will keep their shape once returned to Earth’s gravity! While the road to bioprinting human organs is likely still many years away, these efforts on the space station may move us closer to that much-needed capability for the more than 100,000 people on the wait list for organ transplant.

7. Growing Vitamins

Conditions in space are hard on the human body, and they also can be punishing on food. Regular deliveries of food to the space station refresh the supply of nutritious meals for astronauts. But prepackaged food stored on the Moon or sent to Mars in advance of astronauts could lose some nutritional value over time.

That’s why the BioNutrients experiment is underway. Two different strains of baker’s yeast which are engineered to produce essential nutrients on demand are being checked for shelf life in orbit. Samples of the yeast are being stored at room temperature aboard the space station and then are activated at different intervals, frozen, and returned to Earth for evaluation. These tests will allow scientists to check how long their specially-engineered microbes can be stored on the shelf, while still supplying fresh nutrients that humans need to stay healthy in space. Such microbes must be able to be stored for months, even years, to support the longer durations of exploration missions. If successful, these space-adapted organisms could also be engineered for the potential production of medicines. Similar organisms used in this system could provide fresh foods like yogurt or kefir on demand. Although designed for space, this system also could help provide nutrition for people in remote areas of our planet.

8. Rough and Ready

Everything from paints and container seals to switches and thermal protection systems must withstand the punishing environment of space. Atomic oxygen, charged-particle radiation, collisions with meteoroids and space debris, and temperature extremes (all combined with the vacuum) are just some conditions that are only found in space. Not all of these can be replicated on Earth. In 2001, we addressed this testing problem with the Materials International Space Station Experiment (MISSE). Technologists can send small samples of just about any technology or material into low-Earth orbit for six months or more. Mounted to the exterior of the space station, MISSE has tested more than 4,000 materials. More sophisticated hardware developed over time now supports automatic monitoring that sends photos and data back to researchers on Earth. Renamed the MISSE Flight Facility, this permanent external platform is now owned and operated by the small business, Alpha Space Test & Research Alliance LLC. The woman-owned company is developing two similar platforms for testing materials and technologies on the lunar surface.

9. Parachuting to Earth

Small satellites could provide a cheaper, faster way to deliver small payloads to Earth from the space station. To do just that, the Technology Education Satellite, or TechEdSat, develops the essential technologies with a series of CubeSats built by college students in partnership with NASA. In 2017, TechEdSat-6 deployed from the station, equipped with a custom-built parachute called exo-brake to see if a controlled de-orbit was possible. After popping out of the back of the CubeSat, struts and flexible cords warped the parachute like a wing to control the direction in which it travelled. The exo-brake uses atmospheric drag to steer a small satellite toward a designated landing site. The most recent mission in the series, TechEdSat-10, was deployed from the station in July with an improved version of an exo-brake. The CubeSat is actively being navigated to the target entry point in the vicinity of the NASA’s Wallops Flight Facility on Wallops Island, Virginia.

10. X-ray Vision for a Galactic Position System

Independent navigation for spacecraft in deep space is challenging because objects move rapidly and the distances between are measured in millions of miles, not the mere thousands of miles we’re used to on Earth. From a mission perched on the outside of the station, we were able to prove that X-rays from pulsars could be helpful. A number of spinning neutron stars consistently emit pulsating beams of X-rays, like the rotating beacon of a lighthouse. Because the rapid pulsations of light are extremely regular, they can provide the precise timing required to measure distances.

The Station Explorer for X-Ray Timing and Navigation (SEXTANT) demonstration conducted on the space station in 2017 successfully measured pulsar data and used navigation algorithms to locate the station as it moved in its orbit. The washing machine-sized hardware, which also produced new neutron star science via the Neutron star Interior Composition Explorer (NICER), can now be miniaturized to develop detectors and other hardware to make pulsar-based navigation available for use on future spacecraft.

As NASA continues to identify challenges and problems for upcoming deep space missions such as Artemis, human on Mars, and exploring distant moons such as Titan, STMD will continue to further technology development on the space station and Earth.

Make sure to follow us on Tumblr for your regular dose of space: http://nasa.tumblr.com

Are You Up to the Task of Navigating Space with NASA?

We’re committed to exploration and discovery, journeying to the Moon, Mars, and beyond. But how do we guide our missions on their voyage among the stars? Navigation engineers lead the way!

Using complex mathematical formulas, navigation experts calculate where our spacecraft are and where they’re headed. No matter the destination, navigating the stars is a complicated challenge that faces all our missions. But, we think you’re up to the task!

Our space navigation workbook lets you explore the techniques and mathematical concepts used by navigation engineers. The book delves into groundbreaking navigation innovations like miniaturized atomic clocks, autonomous navigation technologies, using GPS signals at the Moon, and guiding missions through the solar system with X-ray emissions from pulsars — a type of neutron star. It also introduces you to experts working with NASA’s Space Communications and Navigation program at Goddard Space Flight Center in Greenbelt, Maryland.

If you’re a high schooler who dreams of guiding a rover across the rocky surface of Mars or planning the trajectory of an observer swinging around Venus en route to the Sun, this workbook is for you! Download it today and start your adventure with NASA: https://go.nasa.gov/3i7Pzqr

7 Things to Know about the Perseverance Mars Rover

We’re set to launch the Mars 2020 Perseverance rover mission from Cape Canaveral, Florida, on July 30. The rover is loaded with scientific instruments and advanced technology, making it the largest, heaviest and most sophisticated vehicle ever sent to the Red Planet.

What is Perseverance’s mission and what will it do on Mars? Here are seven things to know:

1. Perseverance draws on the NASA – and scientific – spirit of overcoming challenges

Not only does it have to launch during a pandemic and land on a treacherous planet, it has to carry out its science goals:

Searching for signs of past microbial life

Mapping out the planet’s geology and climate

Collecting rock and other samples for future return to Earth

Paving the way for human exploration

We chose the name Perseverance from among the 28,000 essays submitted during the "Name the Rover" contest. Because of the coronavirus pandemic, the months leading up to the launch in particular have required creative problem solving, teamwork and determination.

2. Perseverance builds on the lessons from other Mars rovers

In 1997, our first Mars rover – Sojourner – showed that a robot could rove on the Red Planet. Spirit and Opportunity, which both landed in 2004, found evidence that Mars once had water before becoming a frozen desert.

Curiosity found evidence that Mars’ Gale Crater was home to a lake billions of years ago and that there was an environment that may have sustained microbial life. Perseverance aims to answer the age-old question – are there any signs that life once existed on Mars?

3. Perseverance will land in a place with high potential to find signs of ancient life

The rover will land in Jezero Crater, a 28-mile wide basin north of the Martian equator. A space rock hit the surface long ago, creating the large hole. Between 3 and 4 billion years ago, a river flowed into a body of water in Jezero the size of Lake Tahoe.

4. Perseverance will also collect important data about Mars’ geology and climate

Mars orbiters have collected images and other data about Jezero Crater from about 200 miles above, but finding signs of past life will need much closer inspection. A rover like Perseverance can look for those signs that may be related to ancient life and analyze the context in which they were found to see if the origins were biological.

5. Perseverance is the first leg of a round trip to Mars

This is the first rover to bring a sample-gathering system to Mars that will package promising samples of rocks and other materials for future return to Earth. NASA and ESA are working on the Mars Sample Return campaign, so we can analyze the rocks and sediment with tools too large and complex to send to space.

6. Perseverance will pave the way for human exploration of the Red Planet

Two packages -- one that helps the rover autonomously avoid hazards during landing (TRN) and another that gathers crucial data during the trip through Mars’ atmosphere (MEDLI2) – will help future human missions land safely and with larger payloads on other worlds.

There are two instruments that will specifically help astronauts on the Red Planet. One (MEDA) will provide key information about the planet’s weather, climate and dust activity, while a technology demonstration (MOXIE) aims to extract oxygen from Mars’ mostly carbon-dioxide atmosphere.

7. You get to ride along

Perseverance and other parts of the Mars 2020 spacecraft feature 23 cameras, which is more than any other interplanetary mission in history. Raw images from the camera are set to be released on the mission website.

There are also three silicon chips with the names of nearly 11 million people who signed up to send their names to Mars.

And you can continue to follow the mission on Twitter and Facebook.

Make sure to follow us on Tumblr for your regular dose of space: http://nasa.tumblr.com

Making the Skies Safe for Unmanned Aircraft

Unmanned Aircraft Systems (commonly known as UAS or drones) are typically a smaller aircraft that fly without an onboard pilot. Currently used for research, testing, and aerial-visual purposes, these vehicles could one day carry cargo, or even passengers, through countryside and city landscapes.

UAS are a key component of our Unmanned Aircraft Systems Integration in the National Aairspace Ssystem (UAS in the NAS) project. Our research will help develop the rules so that unmanned aircraft can safely coexist with manned aircraft in the national airspace.

We collaborate with private companies, like Navmar Applied Science Corporation (NASC), to research and test aerodynamically efficient UAS. We also work with government agencies like the Federal Aviation Administration (FAA) to conduct research that will contribute to setting standards and certifications.

We are leading the nation to open a new era in air transportation called Advanced Air Mobility (AAM). AAM will enable safe, sustainable, affordable, and accessible aviation that moves people and cargo between places using a transformed air transportation system and revolutionary new aircraft.

With new cost-and-fuel efficient aircraft and technologies becoming available, UAS will provide substantial benefit to U.S. industry and the public. Such benefits include air-lifted organ transplant deliveries that arrive more quickly and safely than ever before; and search and rescue missions performed with increased speed and accuracy.

There are other benefits too, like pizza being air- dropped to your front door, and less package delivery trucks on the road. The burgeoning landscape of AAM holds many potentials – and it’s our job to help safely and sustainably map out and navigate what that future landscape looks like.

Want to learn the many ways that NASA is with you when you fly? Visit https://www.nasa.gov/aeronautics. Make sure to follow us on Tumblr for your regular dose of space: http://nasa.tumblr.com.

Small Businesses with Big Plans for the Moon and Mars

Today is Small Business Saturday, which the U.S. Small Business Administration (SBA) recognizes as a day to celebrate and support small businesses and all they do for their communities.

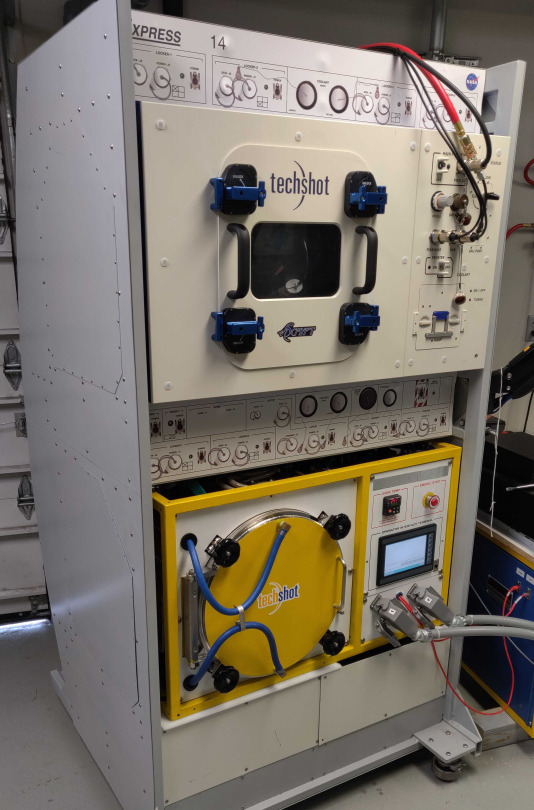

Source: Techshot

We are proud to partner with small businesses across the country through NASA’s Small Business Innovative Research (SBIR) and Small Business Technology Transfer (STTR) programs, which have funded the research, development and demonstration of innovative space technologies since 1982. This year, we’ve awarded 571 SBIR/STTR contracts totaling nearly $180 million to companies who will support our future exploration:

Techshot, Inc. was selected to bioprint micro-organs in a zero-gravity environment for research and testing of organs-on-chip devices, which simulate the physiological functions of body organs at a miniature scale for health research without the need for expensive tests or live subjects.

CertainTech, Inc., with the George Washington University, will demonstrate an improved water recovery system for restoring nontoxic water from wastewater using nanotechnology.

Electrochem, Inc. was contracted to create a compact and lightweight regenerative fuel cell system that can store energy from an electrolyzer during the lunar day to be used for operations during the lunar night.

Source: Electrochem

Small businesses are also developing technologies for the Artemis missions to the Moon and for human and robotic exploration of Mars. As we prepare to land the first woman and next man on the Moon by 2024, these are just a few of the small businesses working with us to make it happen.

Commercial Lunar Payload Delivery Services

Masten Space Systems, Astrobotic and Tyvak Nano-Satellite Systems are three NASA SBIR/STTR alumni now eligible to bid on NASA delivery services to the lunar surface through Commercial Lunar Payload Services (CLPS) contracts. Other small businesses selected as CLPS providers include Ceres Robotics, Deep Space Systems, Intuitive Machines, Moon Express, and Orbit Beyond. Under the Artemis program, these companies could land robotic missions on the Moon to perform science experiments, test technologies and demonstrate capabilities to help the human exploration that will follow. The first delivery could be as early as July 2021.

A Pathfinder CubeSat

One cornerstone of our return to the Moon is a small spaceship called Gateway that will orbit our nearest neighbor to provide more access to the lunar surface. SBIR/STTR alum Advanced Space Systems will develop a CubeSat that will test out the lunar orbit planned for Gateway, demonstrating how to enter into and operate in the unique orbit. The Cislunar Autonomous Positioning System Technology Operations and Navigation Experiment (CAPSTONE) could launch as early as December 2020.

Tipping Point for Moon to Mars

We selected 14 companies as part of our Tipping Point solicitation, which fosters the development of critical, industry-led space capabilities for our future missions. These small businesses all proposed unique technologies that could benefit the Artemis program.

Many of these small businesses are also NASA SBIR/STTR alumni whose Tipping Point awards are related to their SBIR or STTR awards. For example, Infinity Fuel Cell and Hydrogen, Inc. (Infinity Fuel) will develop a power and energy product that could be used for lunar rovers, surface equipment, and habitats. This technology stems from a new type of fuel cell that Infinity Fuel developed with the help of NASA SBIR/STTR awards.

CU Aerospace and Astrobotic are also small businesses whose Tipping Point award can be traced back to technology developed through the NASA SBIR/STTR program. CU Aerospace will build a CubeSat with two different propulsion systems, which will offer high performance at a low cost, and Astrobotic will develop small rover “scouts” that can host payloads and interface with landers on the lunar surface.

Small Businesses, Big Impact

This is just a handful of the small businesses supporting our journey back to the Moon and on to Mars, and just a taste of how they impact the economy and American innovation. We are grateful for the contributions that small businesses make—though they be but “small,” they are fierce.

Make sure to follow us on Tumblr for your regular dose of space: http://nasa.tumblr.com

From Discovering the Secrets of the Universe to In-Space Servicing, We’ve Got The Tools for the Job

If you need to fix something on Earth, you could go to a store, buy the tools you need, and get started. In space, it’s not that easy.

Aside from the obvious challenges associated with space (like it being cold and there being no gravity), developing the right tools requires a great deal of creativity because every task is different, especially when the tools need to be designed from scratch. From the time an engineer dreams up the right tools to the time they are used in space, it can be quite a process.

On Nov. 15, astronauts Luca Parmitano and Drew Morgan began a series of spacewalks to repair an instrument called the Alpha Magnetic Spectrometer (AMS-2) on the exterior of the International Space Station. The first of four spacewalk focused on using specialized tools to remove shields and covers, to gain access to the heart of AMS to perform the repairs, and install a new cooling system.

The debris shield that covered Alpha Magnetic Spectrometer floats away toward Earth as astronaut Drew Morgan successfully releases it.

Once repaired, AMS will continue to help us understand more about the formation of the universe and search for evidence of dark matter and antimatter.

These spacewalks, or extravehicular activities (EVAs), are the most complex of their kind since the servicing of the Hubble Space Telescope. AMS is particularly challenging to repair not only because of the instrument’s complexity and sensitivity, but also because it was never designed to be fixed. Because of this design, it does not have the kinds of interfaces that make spacewalks easier, or the ability to be operated on with traditional multi-purpose tools. These operations are so complex, their design and planning has taken four years. Let’s take a look at how we got ready to repair AMS.

Thinking Outside of the (Tool) Box

When designing the tools, our engineers need to keep in mind various complications that would not come into play when fixing something on Earth. For example, if you put a screw down while you’re on Earth, gravity will keep it there — in space, you have to consistently make sure each part is secure or it will float away. You also have to add a pressurized space suit with limited dexterity to the equation, which further complicates the tool design.

In addition to regular space complications, the AMS instrument itself presents many challenges — with over 300,000 data channels, it was considered too complex to service and therefore was not designed to one day be repaired or updated if needed. Additionally, astronauts have never before cut and reconnected micro-fluid lines (4 millimeters wide, less than the width of the average pencil) during a spacewalk, which is necessary to repair AMS, so our engineers had to develop the tools for this big first.

With all of this necessary out-of-the-box thinking, who better to go to for help than the teams that worked on the most well-known repair missions — the Hubble servicing missions and the space station tool teams? Building on the legacy of these missions, some of our same engineers that developed tools for the Hubble servicing missions and space station maintenance got to work designing the necessary tools for the AMS repair, some reworked from Hubble, and some from scratch. In total, the teams from Goddard Space Flight Center’s Satellite Servicing Projects Division, Johnson Space Center, and AMS Project Office developed 21 tools for the mission.

Designing and Building

Like many great inventions, it all starts with a sketch. Engineers figure out what steps need to be taken to accomplish the task, and imagine the necessary tools to get the job done.

From there, engineers develop a computer-aided design (CAD) model, and get to building a prototype. Tools will then undergo multiple iterations and testing with the AMS repair team and astronauts to get the design just right, until eventually, they are finalized, ready to undergo vibration and thermal vacuum testing to make sure they can withstand the harsh conditions of launch and use in the space environment.

Hex Head Capture Tool Progression:

Hex Head Capture Tool Used in Space:

Practice Makes Perfect

One of the reasons the AMS spacewalks have been four years in the making is because the complexity of the repairs required the astronauts to take extra time to practice. Over many months, astronauts tasked with performing the spacewalks practiced the AMS repair procedures in numerous ways to make sure they were ready for action. They practiced in:

Virtual reality simulations:

The Neutral Buoyancy Laboratory:

The Active Response Gravity Offload System (ARGOS):

Astronauts use this testing to develop and practice procedures in space-like conditions, but also to figure out what works and doesn’t work, and what changes need to be made. A great example is a part of the repair that involves cutting and reconnecting fluid lines. When astronauts practiced cutting the fluid lines during testing here on Earth, they found it was difficult to identify which was the right one to cut based on sight alone.

The tubes on the AMS essentially look the same.

After discussing the concern with the team monitoring the EVAs, the engineers once again got to work to fix the problem.

And thus, the Tube Cutting Guide tool was born! Necessity is the mother of invention and the team could not have anticipated the astronauts would need such a tool until they actually began practicing. The Tube Cutting Guide provides alignment guides, fiducials and visual access to enable astronauts to differentiate between the tubes. After each of eight tubes is cut, a newly designed protective numbered cap is installed to cover the sharp tubing.

Off to Space

With the tools and repair procedures tested and ready to go, they launched to the International Space Station earlier this year. Now they’re in the middle of the main event -- Luca and Drew completed the first spacewalk last Friday, taking things apart to access the interior of the AMS instrument. Currently, there are three other spacewalks scheduled over the course of a month. The next spacewalk will happen on Nov. 22 and will put the Tube Cutting Guide to use when astronauts reconnect the tubes to a new cooling system.

With the ingenuity of our tool designers and engineers, and our astronauts' vigorous practice, AMS will be in good hands.

Check out the full video for the first spacewalk. Below you can check out each of the tools above in action in space!

Debris Shield Worksite: 2:29:16 – Debris Shield Handling Aid 2:35:25 – Hex Head Capture Tool (first) 2:53:31 – #10 Allen Bit 2:54:59 – Capture Cages 3:16:35 – #10 Allen Bit (diagonal side) 3:20:58 – Socket Head Capture Tool 3:33:35 – Hex Head Capture Tool (last) 3:39:35 – Fastener Capture Block 3:40:55 – Debris Shield removal 3:46:46 – Debris Shield jettison

Handrail Installations: 4:00:53 – Diagonal Beam Handrail Install 4:26:09 – Nadir Vacuum Case Handrail Install 4:33:50 – Zenith Vacuum Case Handrail InstallVertical Support Beam (VSB)

Vertical Support Beam (VSB) Worksite: 5:04:21 – Zip Tie Cutter 5:15:27 – VSB Cover Handling Aid 5:18:05 – #10 Allen Bit 5:24:34 – Socket Head Capture Tool 5:41:54 – VSB Cover breaking 5:45:22 – VSB Cover jettison 5:58:20 – Top Spacer Tool & M4 Allen Bit 6:08:25 – Top Spacer removal 7:42:05 - Astronaut shoutout to the tools team

Top 5 Technologies Needed for a Spacecraft to Survive Deep Space

When a spacecraft built for humans ventures into deep space, it requires an array of features to keep it and a crew inside safe. Both distance and duration demand that spacecraft must have systems that can reliably operate far from home, be capable of keeping astronauts alive in case of emergencies and still be light enough that a rocket can launch it.

Missions near the Moon will start when the Orion spacecraft leaves Earth atop the world’s most powerful rocket, the Space Launch System. After launch from Kennedy Space Center in Florida, Orion will travel beyond the Moon to a distance more than 1,000 times farther than where the International Space Station flies in low-Earth orbit, and farther than any spacecraft built for humans has ever ventured. To accomplish this feat, Orion has built-in technologies that enable the crew and spacecraft to explore far into the solar system. Let’s check out the top five:

Systems to Live and Breathe

As humans travel farther from Earth for longer missions, the systems that keep them alive must be highly reliable while taking up minimal mass and volume. Orion will be equipped with advanced environmental control and life support systems designed for the demands of a deep space mission. A high-tech system already being tested aboard the space station will remove carbon dioxide (CO2) and humidity from inside Orion. The efficient system replaces many chemical canisters that would consume up to 10 percent of crew livable area. To save additional space, Orion will also have a new compact toilet, smaller than the one on the space station.

Highly reliable systems are critically important when distant crew will not have the benefit of frequent resupply shipments to bring spare parts from Earth. Even small systems have to function reliably to support life in space, from a working toilet to an automated fire suppression system or exercise equipment that helps astronauts stay in shape to counteract the zero-gravity environment. Distance from home also demands that Orion have spacesuits capable of keeping astronaut alive for six days in the event of cabin depressurization to support a long trip home.

Proper Propulsion

The farther into space a vehicle ventures, the more capable its propulsion systems need to be in order to maintain its course on the journey with precision and ensure its crew can get home.

Orion’s highly capable service module serves as the powerhouse for the spacecraft and provides propulsion capabilities that enable it to go around the Moon and back on exploration missions. The service module has 33 engines of various sizes. The main engine will provide major in-space maneuvering capabilities throughout the mission such as inserting Orion into lunar orbit and firing powerfully enough to exit orbit for a return trip to Earth. The other 32 engines are used to steer and control Orion on orbit.

In part due to its propulsion capabilities, including tanks that can hold nearly 2,000 gallons of propellant and a back up for the main engine in the event of a failure, Orion’s service module is equipped to handle the rigors of travel for missions that are both far and long. It has the ability to bring the crew home in a variety of emergency situations.

The Ability to Hold Off the Heat

Going to the Moon is no easy task, and it’s only half the journey. The farther a spacecraft travels in space, the more heat it will generate as it returns to Earth. Getting back safely requires technologies that can help a spacecraft endure speeds 30 times the speed of sound and heat twice as hot as molten lava or half as hot as the sun.

When Orion returns from the Moon it will be traveling nearly 25,000 mph, a speed that could cover the distance from Los Angeles to New York City in six minutes. Its advanced heat shield, made with a material called AVCOAT, is designed to wear away as it heats up. Orion’s heat shield is the largest of its kind ever built and will help the spacecraft withstand temperatures around 5,000 degrees Fahrenheit during reentry though Earth’s atmosphere.

Before reentry, Orion also will endure a 700-degree temperature range from about minus 150 to 550 degrees Fahrenheit. Orion’s highly capable thermal protection system, paired with thermal controls, will protect it during periods of direct sunlight and pitch black darkness while its crews comfortably enjoy a safe and stable interior temperature of about 77 degrees Fahrenheit.

Radiation Protection

As a spacecraft travels on missions beyond the protection of Earth’s magnetic field, it will be exposed to a harsher radiation environment than in low-Earth orbit with greater amounts of radiation from charged particles and solar storms. This kind of radiation can cause disruptions to critical computers, avionics and other equipment. Humans exposed to large amounts of radiation can experience both acute and chronic health problems ranging from near-term radiation sickness to the potential of developing cancer in the long-term.

Orion was designed from the start with built in system-level features to ensure reliability of essential elements of the spacecraft during potential radiation events. For example, Orion is equipped with four identical computers that each are self-checking, plus an entirely different backup computer, to ensure it can still send commands in the event of a disruption. Engineers have tested parts and systems to a high standard to ensure that all critical systems remain operable even under extreme circumstances.

Orion also has a makeshift storm shelter below the main deck of the crew module. In the event of a solar radiation event, we developed plans for crew on board to create a temporary shelter inside using materials on board. A variety of radiation sensors will also be on the spacecraft to help scientists better understand the radiation environment far away from Earth. One investigation, called AstroRad, will fly on Exploration Mission-1 and test an experimental vest that has the potential to help shield vital organs and decrease exposure from solar particle events.

Constant Communication and Navigation

Spacecraft venturing far from home go beyond the Global Positioning System (GPS) in space and above communication satellites in Earth orbit. To talk with mission control in Houston, Orion’s communication and navigation systems will switch from our Tracking and Data Relay Satellites (TDRS) system used by the International Space Station, and communicate through the Deep Space Network.

Orion is equipped with backup communication and navigation systems to help the spacecraft stay in contact with the ground and orient itself if its primary systems fail. The backup navigation system, a relatively new technology called optical navigation, uses a camera to take pictures of the Earth, Moon and stars and autonomously triangulate Orion’s position from the photos. Its backup emergency communications system doesn’t use the primary system or antennae for high-rate data transfer.

Keep up with all the latest news on our newest, state-of-the art spacecraft by following NASA Orion on Facebook and Twitter.

More on our Moon to Mars plans, here.

Make sure to follow us on Tumblr for your regular dose of space: http://nasa.tumblr.com

5 New Competitions for the Artemis Generation!

A common question we get is, “How can I work with NASA?”

The good news is—just in time for the back-to-school season—we have a slew of newly announced opportunities for citizen scientists and researchers in the academic community to take a shot at winning our prize competitions.

As we plan to land humans on the Moon by 2024 with our upcoming Artemis missions, we are urging students and universities to get involved and offer solutions to the challenges facing our path to the Moon and Mars. Here are five NASA competitions and contests waiting for your ideas on everything from innovative ways to drill for water on other planets to naming our next rover:

1. The BIG Idea Challenge: Studying Dark Regions on the Moon

Before astronauts step on the Moon again, we will study its surface to prepare for landing, living and exploring there. Although it is Earth’s closest neighbor, there is still much to learn about the Moon, particularly in the permanently shadowed regions in and near the polar regions.

Through the annual Breakthrough, Innovative and Game-changing (BIG) Idea Challenge, we’re asking undergraduate and graduate student teams to submit proposals for sample lunar payloads that can demonstrate technology systems needed to explore areas of the Moon that never see the light of day. Teams of up to 20 students and their faculty advisors are invited to propose unique solutions in response to one of the following areas:

• Exploration of permanently shadowed regions in lunar polar regions • Technologies to support in-situ resource utilization in these regions • Capabilities to explore and operate in permanently shadowed regions

Interested teams are encouraged to submit a Notice of Intent by September 27 in order to ensure an adequate number of reviewers and to be invited to participate in a Q&A session with the judges prior to the proposal deadline. Proposal and video submission are due by January 16, 2020.

2. RASC-AL 2020: New Concepts for the Moon and Mars

Although boots on the lunar surface by 2024 is step one in expanding our presence beyond low-Earth orbit, we’re also readying our science, technology and human exploration missions for a future on Mars.

The 2020 Revolutionary Aerospace Systems Concepts – Academic Linkage (RASC-AL) Competition is calling on undergraduate and graduate teams to develop new concepts that leverage innovations for both our Artemis program and future human missions to the Red Planet. This year’s competition branches beyond science and engineering with a theme dedicated to economic analysis of commercial opportunities in deep space.

Competition themes range from expanding on how we use current and future assets in cislunar space to designing systems and architectures for exploring the Moon and Mars. We’re seeking proposals that demonstrate originality and creativity in the areas of engineering and analysis and must address one of the five following themes: a south pole multi-purpose rover, the International Space Station as a Mars mission analog, short surface stay Mars mission, commercial cislunar space development and autonomous utilization and maintenance on the Gateway or Mars-class transportation.

The RASC-AL challenge is open to undergraduate and graduate students majoring in science, technology, engineering, or mathematics at an accredited U.S.-based university. Submissions are due by March 5, 2020 and must include a two-minute video and a detailed seven to nine-page proposal that presents novel and robust applications that address one of the themes and support expanding humanity’s ability to thrive beyond Earth.

3. The Space Robotics Challenge for Autonomous Rovers

Autonomous robots will help future astronauts during long-duration missions to other worlds by performing tedious, repetitive and even strenuous tasks. These robotic helpers will let crews focus on the more meticulous areas of exploring. To help achieve this, our Centennial Challenges initiative, along with Space Center Houston of Texas, opened the second phase of the Space Robotics Challenge. This virtual challenge aims to advance autonomous robotic operations for missions on the surface of distant planets or moons.

This new phase invites competitors 18 and older from the public, industry and academia to develop code for a team of virtual robots that will support a simulated in-situ resource utilization mission—meaning gathering and using materials found locally—on the Moon.

The deadline to submit registration forms is December 20.

4. Moon to Mars Ice & Prospecting Challenge to Design Hardware, Practice Drilling for Water on the Moon and Mars

A key ingredient for our human explorers staying anywhere other than Earth is water. One of the most crucial near-term plans for deep space exploration includes finding and using water to support a sustained presence on our nearest neighbor and on Mars.

To access and extract that water, NASA needs new technologies to mine through various layers of lunar and Martian dirt and into ice deposits we believe are buried beneath the surface. A special edition of the RASC-AL competition, the Moon to Mars Ice and Prospecting Challenge, seeks to advance critical capabilities needed on the surface of the Moon and Mars. The competition, now in its fourth iteration, asks eligible undergraduate and graduate student teams to design and build hardware that can identify, map and drill through a variety of subsurface layers, then extract water from an ice block in a simulated off-world test bed.

Interested teams are asked to submit a project plan detailing their proposed concept’s design and operations by November 14. Up to 10 teams will be selected and receive a development stipend. Over the course of six months teams will build and test their systems in preparation for a head-to-head competition at our Langley Research Center in June 2020.

5. Name the Mars 2020 Rover!

Red rover, red rover, send a name for Mars 2020 right over! We’re recruiting help from K-12 students nationwide to find a name for our next Mars rover mission.

The Mars 2020 rover is a 2,300-pound robotic scientist that will search for signs of past microbial life, characterize the planet's climate and geology, collect samples for future return to Earth, and pave the way for human exploration of the Red Planet.

K-12 students in U.S. public, private and home schools can enter the Mars 2020 Name the Rover essay contest. One grand prize winner will name the rover and be invited to see the spacecraft launch in July 2020 from Cape Canaveral Air Force Station in Florida. To enter the contest, students must submit by November 1 their proposed rover name and a short essay, no more than 150 words, explaining why their proposed name should be chosen.

Just as the Apollo program inspired innovation in the 1960s and '70s, our push to the Moon and Mars is inspiring students—the Artemis generation—to solve the challenges for the next era of space exploration.

For more information on all of our open prizes and challenges, visit: https://www.nasa.gov/solve/explore_opportunities

Make sure to follow us on Tumblr for your regular dose of space: http://nasa.tumblr.com

How did your perspective on Earth & humanity change from space?

It’s National Composites Week! Wait, what’s a composite?

This week, we’re celebrating National Composites Week, which CompositesWorld says is about shedding some light on how “composite materials and composites manufacturing contributes to the products and structures that shape the American manufacturing landscape today.”

What exactly are composites and why are we talking about them?

Composites are building materials that we use to make airplanes, spacecraft and structures or instruments, such as space telescopes. But why are they special?

Composites consist of two or more materials, similar to a sandwich. Each ingredient in a sandwich could be eaten individually, but combining them is when the real magic happens. Sure, you could eat a few slices of cold cheese chased with some floppy bread. But real talk: buttery, toasted bread stuffed with melty, gooey Gouda makes a grilled cheese a much more satisfying nosh.

With composites—like our sandwich—the different constituent parts each have special properties that are enhanced when combined. Take carbon fibers which are strong and rigid. Their advantage compared to other structural materials is that they are much lighter than metals like steel and aluminum. However, in order to build structures with carbon fibers, they have to be held together by another material, which is referred to as a matrix. Carbon Fiber Reinforced Polymer is a composite consisting of carbon fibers set in a plastic matrix, which yields an extremely strong, lightweight, high-performing material for spacecraft.

Composites can also be found on the James Webb Space Telescope. They support the telescope’s beryllium mirrors, science instruments and thermal control systems and must be exquisitely stable to keep the segments aligned.

We invest in a variety of composite technology research to advance the use of these innovative materials in things like fuel tanks on spacecraft, trusses or structures and even spacesuits. Here are a few exciting ways our Space Technology Mission Directorate is working with composites:

Deployable structures on small spacecraft

We’re developing deployable composite booms for future deep space small satellite missions. These new structures are being designed to meet the unique requirements of small satellites, things like the ability to be packed into very small volumes and stored for long periods of time without getting distorted.

A new project, led by our Langley Research Center and Ames Research Center, called the Advanced Composite Solar Sail System will test deployment of a composite boom solar sail system in low-Earth orbit. This mission will demonstrate the first use of composite booms for a solar sail in orbit as well as new sail packing and deployment systems.

Nano (teeny tiny) composites

We are working alongside 11 universities, two companies and the Air Force Research Laboratory through the Space Technology Research Institute for Ultra-Strong Composites by Computational Design (US-COMP). The institute is receiving $15 million over five years to accelerate carbon nanotube technologies for ultra-high strength, lightweight aerospace structural materials. This institute engages 22 professors from universities across the country to conduct modeling and experimental studies of carbon nanotube materials on an atomistic molecular level, macro-scale and in between. Through collaboration with industry partners, it is anticipated that advances in laboratories could quickly translate to advances in manufacturing facilities that will yield sufficient amounts of advanced materials for use in NASA missions.

Through Small Business Innovative Research contracts, we’ve also invested in Nanocomp Technologies, Inc., a company with expertise in carbon nanotubes that can be used to replace heavier materials for spacecraft, defense platforms, and other commercial applications.

Nanocomp’s Miralon™ YM yarn is made up of pure carbon nanotube fibers that can be used in a variety of applications to decrease weight and provide enhanced mechanical and electrical performance. Potential commercial use for Miralon yarn includes antennas, high frequency digital/signal and radio frequency cable applications and embedded electronics. Nanocomp worked with Lockheed Martin to integrate Miralon sheets into our Juno spacecraft.

Composites for habitats

At last spring’s 3D-Printed Habitat Challenge the top two teams used composite materials in their winning habitat submissions. The multi-phase competition challenged teams to 3D print one-third scale shelters out of recyclables and materials that could be found on deep space destinations, like the Moon and Mars.

After 30 hours of 3D-printing over four days of head-to-head competition, the structures were subjected to several tests and evaluated for material mix, leakage, durability and strength. New York-based AI. SpaceFactory won first place using a polylactic acid plastic, similar to materials available for Earth-based, high-temperature 3D printers.

This material was infused with micro basalt fibers as well, and the team was awarded points during judging because major constituents of the polylactic acid material could be extracted from the Martian atmosphere.

Second place was awarded to Pennsylvania State University who utilized a mix of Ordinary Portland Cement, a small amount of rapid-set concrete, and basalt fibers, with water.

These innovative habitat concepts will not only further our deep space exploration goals, but could also provide viable housing solutions right here on Earth.

Student research in composites

We are also supporting the next generation of engineers, scientists and technologists working on composites through our Space Technology Research Grants. Some recently awarded NASA Space Technology Fellows—graduate students performing groundbreaking, space technology research on campus, in labs and at NASA centers—are studying the thermal conductivity of composites and an optimized process for producing carbon nanotubes and clean energy.

We work with composites in many different ways in pursuit of our exploration goals and to improve materials and manufacturing for American industry. If you are a company looking to participate in National Composites Week, visit: https://www.nationalcompositesweek.com.

Make sure to follow us on Tumblr for your regular dose of space: http://nasa.tumblr.com

5 Out-of-this-world Facts About Our Iconic Vehicle Assembly Building!

The Vehicle Assembly Building, or VAB, at our Kennedy Space Center in Florida, is the only facility where assembly of a rocket occurred that carried humans beyond low-Earth orbit and on to the Moon. For 30 years, its facilities and assets were used during the Space Shuttle Program and are now available to commercial partners as part of our agency’s plan in support of a multi-user spaceport. To celebrate the VAB’s continued contribution to humanity’s space exploration endeavors, we’ve put together five out-of-this-world facts for you!

1. It’s one of the largest buildings in the world by area, the VAB covers eight acres, is 525 feet tall and 518 feet wide.

Aerial view of the Vehicle Assembly Building with a mobile launch tower atop a crawler transporter approaching the building.

2. The VAB was constructed for the assembly of the Apollo/Saturn V Moon rocket, the largest rocket made by humans at the time.

An Apollo/Saturn V facilities Test Vehicle and Launch Umbilical Tower (LUT) atop a crawler-transporter move from the Vehicle Assembly Building (VAB) on the way to Pad A on May 25, 1966.

3. The building is home to the largest American flag, a 209-foot-tall, 110-foot-wide star spangled banner painted on the side of the VAB.

Workers painting the Flag on the Vehicle Assembly Building on January 2, 2007.

4. The tallest portions of the VAB are its 4 high bays. Each has a 456-foot-high door. The doors are the largest in the world and take about 45 minutes to open or close completely.

A mobile launcher, atop crawler-transporter 2, begins the move into High Bay 3 at the Vehicle Assembly Building (VAB) on Sept. 8, 2018.

5. After spending more than 50 years supporting our human spaceflight programs, the VAB received its first commercial tenant – Northrop Grumman Corporation – on August 16, 2019!

A model of Northrop Grumman’s OmegA launch vehicle is flanked by the U.S. flag and a flag bearing the OmegA logo during a ribbon-cutting ceremony Aug. 16 in High Bay 2 of the Vehicle Assembly Building.

Whether the rockets and spacecraft are going into Earth orbit or being sent into deep space, the VAB will have the infrastructure to prepare them for their missions.

Make sure to follow us on Tumblr for your regular dose of space: http://nasa.tumblr.com.

Smoke Gets In Your Eyes…and Our Instruments

Fires are some of the most dynamic and dramatic natural phenomena. They can change rapidly, burning natural landscapes and human environments alike. Fires are a natural part of many of Earth’s ecosystems, necessary to replenish soil and for healthy plant growth. But, as the planet warms, fires are becoming more intense, burning longer and hotter.

Right now, a fleet of vehicles and a team of scientists are in the field, studying how smoke from those fires affects air quality, weather and climate. The mission? It’s called FIREX-AQ. They’re working from the ground up to the sky to measure smoke, find out what’s in it, and investigate how it affects our lives.

Starting on the ground, the Langley Aerosol Research Group Experiment (LARGE) operates out of a large van. It’s one of two such vans working with the campaign, along with some other, smaller vans. It looks a little like a food truck, but instead of a kitchen, the inside is packed full of science instruments.

The team drives the van out into the wilderness to take measurements of smoke and tiny particles in the air at the ground level. This is important for a few reasons: First of all, it’s the stuff we’re breathing! It also gives us a look at smoke overnight, when the plumes tend to sink down out of the atmosphere and settle near the ground until temperatures heat back up with the Sun. The LARGE group camps out with their van full of instruments, taking continuous measurements of smoke…and not getting much sleep.

Just a little higher up, NOAA’s Twin Otter aircraft can flit down close to where the fires are actually burning, taking measurements of the smoke and getting a closer look at the fires themselves. The Twin Otters are known as “NOAA’s workhorses” because they’re easily maneuverable and can fly nice and slow to gather measurements, topping out at about 17,000 feet.

Then, sometimes flying at commercial plane height (30,000 feet) and swooping all the way down to 500 feet above the ground, NASA’s DC-8 is packed wing to wing with science instruments. The team onboard the DC-8 is looking at more than 500 different chemicals in the smoke.

The DC-8 does some fancy flying, crisscrossing over the fires in a maneuver called “the lawnmower” and sometimes spiraling down over one vertical column of air to capture smoke and particles at all different heights. Inside, the plane is full of instrument racks and tubing, capturing external air and measuring its chemical makeup. Fun fact: The front bathroom on the DC-8 is closed during science flights to make sure the instruments don’t accidentally measure anything ejected from the plane.

Finally, we make it all the way up to space. We’ve got a few different mechanisms for studying fires already mounted on satellites. Some of the satellites can see where active fires are burning, which helps scientists and first responders keep an eye on large swaths of land.

Some satellites can see smoke plumes, and help researchers track them as they move across land, blown by wind.

Other satellites help us track weather and forecast how the fires might behave. That’s important for keeping people safe, and it helps the FIREX-AQ team know where to fly and drive when they’ll get the most information. These forecasts use computer models, based on satellite observations and data about how fires and smoke behave. FIREX-AQ’s data will be fed back into these models to make them even more accurate.

Learn more about how NASA is studying fires from the field, here.

Make sure to follow us on Tumblr for your regular dose of space: http://nasa.tumblr.com.

Out of the Lab and Into the Air

As we celebrate the 50th anniversary of the first Apollo Moon landing, remember that many Apollo astronauts, including Neil Armstrong, the first person on the Moon, were test pilots who flew experimental planes for NASA in our earliest days. Since long before we landed on the Moon, aeronautics has been a key piece of our mission.

The U.S. founded the National Advisory Committee on Aeronautics (NACA), our predecessor, in 1914. NACA, collaborating with the U.S. Air Force, pioneered the X-1 aircraft, the first crewed plane to achieve supersonic speeds. NACA was largely responsible for turning the slow, cloth-and-wood biplanes of the early 1900s into the sleek, powerful jets of today.

When NACA was absorbed by the newly formed NASA in 1958, we continued NACA’s mission, propelling American innovation in aviation. Today, our portfolio of aeronautics missions and new flight technologies is as robust as ever. Below are seven of our innovations flying out of the lab and into the air, getting you gate-to-gate safely and on time while transforming aviation into an economic engine!

1. X-59 QueSST

Our X-59 Quiet SuperSonic Technology (QueSST) flies faster than the speed of sound without the window-shattering sonic boom. This innovation may kick off a new generation of quiet, supersonic planes that can fly over land without disturbing those below. Once adopted, QueSST’s technologies could drastically reduce the time it takes to fly across the U.S. and even to other countries worldwide!

2. X-57 Maxwell

Our X-57 Maxwell will be the first all-electric X-plane, demonstrating the benefits distributed electric propulsion may have for future aviation. The Maxwell is named for Scottish physicist James Clerk Maxwell, who is known for his theories on electricity and electromagnetism. The name is also a play on words because, as X-57 engineer Nick Borer said, “It has the maximum number of propellers.”

3. Airborne Science

Our airborne science program provides Earth scientists and astrophysicists with the unique insights that can be gleaned from the air and above the clouds. By flying aircraft with Earth science instruments and advanced telescopes, we can gather high resolution data about our changing Earth and the stars above. Airborne science outreach specialist (and champion aerobatics pilot) Susan Bell highlights Fire Influence on Regional to Global Environments Experiment – Air Quality (FIREX-AQ), a joint mission with the National Oceanic and Atmospheric Administration (NOAA).

“FIREX-AQ will investigate the impact of wildfires and agricultural fires on air quality,” Susan said. “Living in the Western U.S., I witness firsthand the impact that smoke can have on the communities we live in and up in the air as a pilot.”

4. Search and Rescue

Our Search and Rescue (SAR) office serves as the technology development arm of the international satellite-aided search and rescue program, Cospas-Sarsat. Recently, the Federal Aviation Administration adopted SAR’s guidance regarding the testing and installation of the NASA-developed beacons required for planes. These recommendations will greatly improve aviation beacon performance and, ultimately, save more lives.

SAR developed the recommendations through crash test research at our Langley Research Center’s gantry in Hampton, Virginia, where Neil Armstrong and Buzz Aldrin trained for the Apollo Moon landing!

5. MADCAT

Our Mission Adaptive Digital Composite Aerostructure Technologies (MADCAT) team at our Ames Research Center in California’s Silicon Valley uses strong, lightweight carbon fiber composites to design airplane wings that can adapt on the fly. The composite materials are used to create “blocks,” modular units that can be arranged in repeating lattice patterns — the same crisscrossing patterns you might see in a garden fence!

6. RVLT

Our Revolutionary Vertical Lift Technology (RVLT) project leverages the agency’s aeronautics expertise to advance vertical flight capabilities in the U.S. The RVLT project helps design and test innovative new vehicle designs, like aircraft that can take off like a helicopter but fly like a plane. Additionally, the project uses computer models of the complex airflow surrounding whirring rotors to design vehicles that make less noise!

7. Moon to Mars

We’re with you when you fly — even on Mars! The 1958 law that established the agency charged us with solving the problems of flight within the atmosphere… but it didn’t say WHICH atmosphere. We’re applying our aeronautics expertise to the thin atmosphere of Mars, developing technologies that will enable flight on the Red Planet. In fact, a small, robotic helicopter will accompany the Mars 2020 rover, becoming the first heavier-than-air vehicle to fly on — err, above — Mars!

Make sure to follow us on Tumblr for your regular dose of space: http://nasa.tumblr.com.

A Day in Our Lives With X-Ray Tech

On July 23, 1999, NASA’s Chandra X-ray Observatory, the most powerful X-ray telescope ever built, was launched into space. Since then, Chandra has made numerous amazing discoveries, giving us a view of the universe that is largely hidden from view through telescopes that observe in other types of light.

The technology behind X-ray astronomy has evolved at a rapid pace, producing and contributing to many spinoff applications you encounter in day-to-day life. It has helped make advancements in such wide-ranging fields as security monitoring, medicine and bio-medical research, materials processing, semi-conductor and microchip manufacturing and environmental monitoring.

7:00 am: Your hand has been bothering you ever since you caught that ball at the family reunion last weekend. Your doctor decides it would be a good idea for an X-ray to rule out any broken bones. X-rays are sent through your hand and their shadow is captured on a detector behind it. You’re relieved to hear nothing is broken, though your doctor follows up with an MRI to make sure the tendons and ligaments are OK.

Two major developments influenced by X-ray astronomy include the use of sensitive detectors to provide low dose but high-resolution images, and the linkage with digitizing and image processing systems. Because many diagnostic procedures, such as mammographies and osteoporosis scans, require multiple exposures, it is important that each dosage be as low as possible. Accurate diagnoses also depend on the ability to view the patient from many different angles. Image processing systems linked to detectors capable of recording single X-ray photons, like those developed for X-ray astronomy purposes, provide doctors with the required data manipulation and enhancement capabilities. Smaller hand-held imaging systems can be used in clinics and under field conditions to diagnose sports injuries, to conduct outpatient surgery and in the care of premature and newborn babies.

8:00 am: A technician places your hand in a large cylindrical machine that whirs and groans as the MRI is taken. Unlike X-rays that can look at bones and dense structures, MRIs use magnets and short bursts of radio waves to see everything from organs to muscles.

MRI systems are incredibly important for diagnosing a whole host of potential medical problems and conditions. X-ray technology has helped MRIs. For example, one of the instruments developed for use on Chandra was an X-ray spectrometer that would precisely measure the energy signatures over a key range of X-rays. In order to make these observations, this X-ray spectrometer had to be cooled to extremely low temperatures. Researchers at our Goddard Space Flight Center in Greenbelt, Maryland developed an innovative magnet that could achieve these very cold temperatures using a fraction of the helium that other similar magnets needed, thus extending the lifetime of the instrument’s use in space. These advancements have helped make MRIs safer and require less maintenance.

11:00 am: There’s a pharmacy nearby so you head over to pick up allergy medicine on the way home from your doctor’s appointment.

X-ray diffraction is the technique where X-ray light changes its direction by amounts that depend on the X-ray energy, much like a prism separates light into its component colors. Scientists using Chandra take advantage of diffraction to reveal important information about distant cosmic sources using the observatory’s two gratings instruments, the High Energy Transmission Grating Spectrometer (HETGS) and the Low Energy Transmission Grating Spectrometer (LETGS).

X-ray diffraction is also used in biomedical and pharmaceutical fields to investigate complex molecular structures, including basic research with viruses, proteins, vaccines and drugs, as well as for cancer, AIDS and immunology studies. How does this work? In most applications, the subject molecule is crystallized and then irradiated. The resulting diffraction pattern establishes the composition of the material. X-rays are perfect for this work because of their ability to resolve small objects. Advances in detector sensitivity and focused beam optics have allowed for the development of systems where exposure times have been shortened from hours to seconds. Shorter exposures coupled with lower-intensity radiation have allowed researchers to prepare smaller crystals, avoid damage to samples and speed up their data runs.

12:00 pm: Don’t forget lunch. There’s not much time after your errands so you grab a bag of pretzels. Food safety procedures for packaged goods include the use of X-ray scans to make sure there is quality control while on the production line.

Advanced X-ray detectors with image displays inspect the quality of goods being produced or packaged on a production line. With these systems, the goods do not have to be brought to a special screening area and the production line does not have to be disrupted. The systems range from portable, hand-held models to large automated systems. They are used on such products as aircraft and rocket parts and structures, canned and packaged foods, electronics, semiconductors and microchips, thermal insulations and automobile tires.

2:00 pm: At work, you are busy multi-tasking across a number of projects, running webinar and presentation software, as well as applications for your calendar, spreadsheets, word processing, image editing and email (and perhaps some social media on the side). It’s helpful that your computer can so easily handle running many applications at once.

X-ray beam lithography can produce extremely fine lines and has applications for developing computer chips and other semiconductor related devices. Several companies are researching the use of focused X-ray synchrotron beams as the energy source for this process, since these powerful beams produce good pattern definition with relatively short exposure times. The grazing incidence optics — that is, the need to skip X-rays off a smooth mirror surface like a stone across a pond and then focus them elsewhere — developed for Chandra were the highest precision X-ray optics in the world and directly influenced this work.

7:00 pm: Dream vacation with your family. Finally! You are on your way to the Bahamas to swim with the dolphins. In the line for airport security, carry-on bags in hand, you are hoping you’ve remembered sunscreen. Shoes off! All items placed in the tray. Thanks to X-ray technology, your bags will be inspected quickly and you WILL catch your plane…

The first X-ray baggage inspection system for airports used detectors nearly identical to those flown in the Apollo program to measure fluorescent X-rays from the Moon. Its design took advantage of the sensitivity of the detectors that enabled the size, power requirements and radiation exposure of the system to be reduced to limits practical for public use, while still providing adequate resolution to effectively screen baggage. The company that developed the technology later developed a system that can simultaneously image, on two separate screens, materials of high atomic weight (e.g. metal hand guns) and materials of low atomic weight (e.g. plastic explosives) that pass through other systems undetected. Variations of these machines are used to screen visitors to public buildings around the world.

Check out Chandra’s 20th anniversary page to see how they are celebrating.

Make sure to follow us on Tumblr for your regular dose of space: http://nasa.tumblr.com.

Science Coming Soon to a Space Station Near You

Dozens of science experiments will soon make their red carpet debuts on the International Space Station. They will arrive courtesy of a Dragon cargo spacecraft launched from Cape Canaveral Air Force Station in Florida. The starring players include investigations into 3D printing organ tissue, breaking up rocks and building bones.

Meet some of the experiments blasting off that could lead to the development of new technologies as well as improve life on Earth.

Grab yourself an (organ) tissue

Scientists and medical professionals have long dreamed of the day 3D printers can be used to create useable human organs. But pesky gravity seems to always get in the way.

Enter microgravity. The new BioFabrication Facility (BFF) will provide a platform to attempt the creation of this organ tissue on the space station, a potential first step towards creating entire human organs in space.

Put down your pickaxe and pick up some microbes

Extracting minerals from rocks doesn’t always require brute force. Microbes can be deployed for the same purpose in a process called bio-mining. While common on Earth, the method still needs to be explored in space to see if it can eventually help explorers on the Moon and Mars. The BioRock investigation will examine the interactions between microbes and rocks and see if microgravity could limit the use of bio-mining by restricting bacterial growth.

Keep rolling along

Goodyear Tire will investigate if microgravity can help improve the silica design process, silica rubber formation and tire manufacturing. This investigation could lead to improvements like better tire performance and increased fuel efficiency, putting a bit of cash back in your pocket.

When space gets on our nerves